[email protected]

A Publication of the FREE Wind Press - May be re-printed for personal use only

Copyright (C) 2007 TRUE-NORTH Power Systems

For commercial or non-profit publication contact TRUE-NORTH Power Systems

Lion's Head ON N0H 1W0 - (519) 793-3290

A Publication of the FREE Wind Press - May be re-printed for personal use only

Copyright (C) 2007 TRUE-NORTH Power Systems

For commercial or non-profit publication contact TRUE-NORTH Power Systems

Lion's Head ON N0H 1W0 - (519) 793-3290

Issue 4:1 Headlines: January 2006

Sneak Peak at the Sleek New LAKOTA SC "Storm Chaser" for 2006

The new LAKOTA SC "Storm Chaser" is coming out strong for 2006. Sounds a bit like a marketing pitch but believe me these are the most important improvements in the LAKOTA machine since it was first developed from the successful Wind Baron series back in 1999-2000. They've tightened the machining tolerances in many components and that brings it in line with many Aerospace grade components. The first thing you notice is the sleek new casting with a redesigned spring attachments that will eliminate stress and the high frequency wear that can happen during high wind events in excess of 50-60mph. During the Nov 6, 11 and 14 extreme wind events in Southern Ontario last fall many LAKOTAs experienced sustained winds above 50mph and peak gusts above 60mph. The high frequency vibrations in the spring attachment points lead to some failures that could have been avoided if they had had this improved attachment method.

More important than the looks however is what's been done inside. Tighter tolerances yes, but they've also improved overall performance efficiency by changing the brush contact geometry and adding as second set of brushes . . the more advanced OB1 design has always had this dual brush configuration but it was originally not used on the LAKOTA since the extra cost was not justified for the lower power range. It appears now that they are willing to spare no expense to make LAKOTA the most rugged and reliable machine in it's class . . . . with two sets of brushes you can use lighter brush springs and much lower contact pressure, to further lengthen wear life and reduce the high current induced heat during extreme wind events . . like storms. If you remember our "Storm Chaser" stories back in Nov 2004 and again in winter 2005 . . The LAKOTA was always designed to survive winds even above 60-70mph and I have seen many examples of them doing just that. You may have seen pictures in the past of the LAKOTA on one our test tower still working after winds strong enough to bend the tower over 45 degrees. With these new dual brushes and about another 5-6 degrees of pitch furl, new 2006 LAKOTA should take anything mother nature has short of a hurricane or tornado.

Wait there's more . . new bearing front seal and access panel gaskets top and bottom to better keep any moisture from entering during rainy cooldowns after a storm and a stronger yaw component, higher grade casting material and a number of assembly process improvements designed to ensure every machine can safely and continuously exceed it's rated power by at least 140%. That means that when other machines are shutting down and protecting themselves from high winds your 900w LAKOTA 2006 will be happily pumping out well in excess of 1200-1300 watts even in winds above 50mph. No need to baby it when storms appear. It's a real "Storm Chaser".

All in all, this is a solid evolution of the LAKOTA with great abilities for the power range of 500-1500 watts and I can see its come through some well thought out improvements in this latest iteration. After visiting the factory this past week and seeing the dedication of the designers, assemblers and finishers, I think the LAKOTA is really ready for prime time, and anyone will be hard pressed to get much more out of a 3.4 square meters cross section in any wind high or low. If you want more power than that you'll just have to get a bigger blade . . enter the OB1 . . More on the OB1 below.

The new LAKOTA SC "Storm Chaser" is coming out strong for 2006. Sounds a bit like a marketing pitch but believe me these are the most important improvements in the LAKOTA machine since it was first developed from the successful Wind Baron series back in 1999-2000. They've tightened the machining tolerances in many components and that brings it in line with many Aerospace grade components. The first thing you notice is the sleek new casting with a redesigned spring attachments that will eliminate stress and the high frequency wear that can happen during high wind events in excess of 50-60mph. During the Nov 6, 11 and 14 extreme wind events in Southern Ontario last fall many LAKOTAs experienced sustained winds above 50mph and peak gusts above 60mph. The high frequency vibrations in the spring attachment points lead to some failures that could have been avoided if they had had this improved attachment method.

More important than the looks however is what's been done inside. Tighter tolerances yes, but they've also improved overall performance efficiency by changing the brush contact geometry and adding as second set of brushes . . the more advanced OB1 design has always had this dual brush configuration but it was originally not used on the LAKOTA since the extra cost was not justified for the lower power range. It appears now that they are willing to spare no expense to make LAKOTA the most rugged and reliable machine in it's class . . . . with two sets of brushes you can use lighter brush springs and much lower contact pressure, to further lengthen wear life and reduce the high current induced heat during extreme wind events . . like storms. If you remember our "Storm Chaser" stories back in Nov 2004 and again in winter 2005 . . The LAKOTA was always designed to survive winds even above 60-70mph and I have seen many examples of them doing just that. You may have seen pictures in the past of the LAKOTA on one our test tower still working after winds strong enough to bend the tower over 45 degrees. With these new dual brushes and about another 5-6 degrees of pitch furl, new 2006 LAKOTA should take anything mother nature has short of a hurricane or tornado.

Wait there's more . . new bearing front seal and access panel gaskets top and bottom to better keep any moisture from entering during rainy cooldowns after a storm and a stronger yaw component, higher grade casting material and a number of assembly process improvements designed to ensure every machine can safely and continuously exceed it's rated power by at least 140%. That means that when other machines are shutting down and protecting themselves from high winds your 900w LAKOTA 2006 will be happily pumping out well in excess of 1200-1300 watts even in winds above 50mph. No need to baby it when storms appear. It's a real "Storm Chaser".

All in all, this is a solid evolution of the LAKOTA with great abilities for the power range of 500-1500 watts and I can see its come through some well thought out improvements in this latest iteration. After visiting the factory this past week and seeing the dedication of the designers, assemblers and finishers, I think the LAKOTA is really ready for prime time, and anyone will be hard pressed to get much more out of a 3.4 square meters cross section in any wind high or low. If you want more power than that you'll just have to get a bigger blade . . enter the OB1 . . More on the OB1 below.

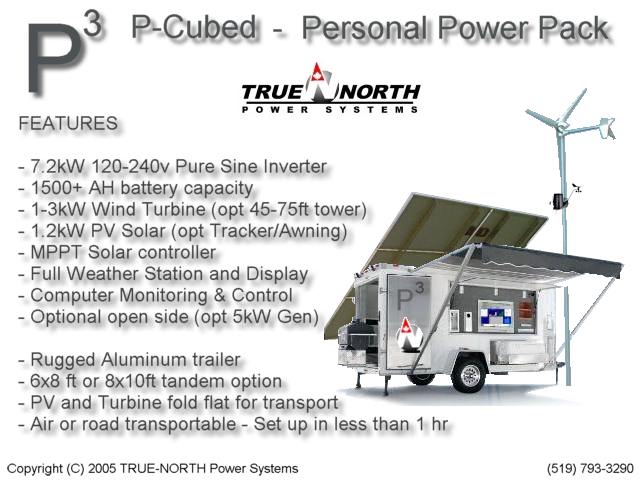

P-Cubed - The Personal Power Pack

Ever wish you could take it with you . . your own personal power system. . . Up to the cottage or off to a remote home . . where the electrons don't roam. Well you can now. TRUE-NORTH Power Systems business VISION has always been "Personal Power - Any Where - Any Time" and our MISSION is to provide personal power systems anywhere on the planet they are needed. One of the difficulties is getting all the components to the right location and properly assembled so they can produce power quickly from whatever local energy is available be it wind, solar or hydro.

As a result of our successful training program we have developed a standard mix of components that can be easily integrated and transported anywhere by trailer or container. Similar systems have be built in the past but largely for expensive government or research operations. The P-Cubed "Personal Power Pack" trailer mounted systems aims to lower the cost and improve the transportability of these systems in several standardized power and equipment configurations. . . for training, research, education and remote operations and personal use.

The educational system will be in operation hopefully on one of our upcoming weekend workshops in the spring. It will include both wind and solar generators aw well as a standard generator intertie and the ability to Net-Meter. . . but it will also have a wireless weather monitoring and data logging station with a portable computer that can collect and display both weather and performance information in real time. Normally as 24ft mast and LAKOTA turbine with about 700-800 watts of solar will set up in less than an hour and provide up to 7.3 kW of power from a 1500AH sealed battery pack.

Ever wish you could take it with you . . your own personal power system. . . Up to the cottage or off to a remote home . . where the electrons don't roam. Well you can now. TRUE-NORTH Power Systems business VISION has always been "Personal Power - Any Where - Any Time" and our MISSION is to provide personal power systems anywhere on the planet they are needed. One of the difficulties is getting all the components to the right location and properly assembled so they can produce power quickly from whatever local energy is available be it wind, solar or hydro.

As a result of our successful training program we have developed a standard mix of components that can be easily integrated and transported anywhere by trailer or container. Similar systems have be built in the past but largely for expensive government or research operations. The P-Cubed "Personal Power Pack" trailer mounted systems aims to lower the cost and improve the transportability of these systems in several standardized power and equipment configurations. . . for training, research, education and remote operations and personal use.

The educational system will be in operation hopefully on one of our upcoming weekend workshops in the spring. It will include both wind and solar generators aw well as a standard generator intertie and the ability to Net-Meter. . . but it will also have a wireless weather monitoring and data logging station with a portable computer that can collect and display both weather and performance information in real time. Normally as 24ft mast and LAKOTA turbine with about 700-800 watts of solar will set up in less than an hour and provide up to 7.3 kW of power from a 1500AH sealed battery pack.

In collaboration with a Canadian outreach program, we are planning to deploy the first of these operational P-Cubes with a mobile Aids clinic in Africa this coming summer. With up to three more going to Canadian universities and Ontario schools for research and renewable energy education awareness in Canada. The price for the basic configuration of these systems is targeted at under $15,000 with LAKOTA turbine, 200W solar PV, 500AH battery pack and 2500W Inverter. Beefier power systems with integrated weather stations, lots more PV and 75ft tower, 2000AH batteries and 7kW of sure sine wave under $40K. We've already had a number of strong inquiries for these very versatile power stations from mining and forestry companies as well a government and educational customers, so I expect this will quickly become a popular line of fully integrated ready to go Power Cubes this coming summer. If you come to one of our spring workshops in April or May you'll get to play with our training model.

OB1 Update - Testing in Canada

So what's up with OB1 . . I saw more progress on the OB1 controller and the blade tooling and we are getting word they'll soon have the necessary funding to launch. . . unfortunately still no firm date as of 17 Jan 06, however, I expect to have a fully operational machine to begin testing in Canada within a few weeks March 2006. I've had a chance to play with the OB1 Commander on my LAKOTA last fall and was fascinated to see it "hunting" for the power sweet spot as the wind gusts change and flow. With a capability of up to 5kW this controller promises to be a really efficient turbine manager that can be retrofit to even competitor machines with a generic software load. The basic principles of Pulse Width Modulation (PWM) control have been around for decades with solar PV systems just line the LAKOTA heritage stems from Wind Baron Neo . . the world's first permanent magnet alternator small wind turbine. The breakthrough was the use of high powered Neodymium magnets. . . hence the name Neo.

With the development of the OB1, back in 2000, Aeromag produced the first microprocessor controlled PWM turbine. . . and now the OB1 Commander firmware has allowed that to be extended to the dynamic world of micro-gust management. The original patent for PWM controllers dates back to the early 80s. Since then many solar and some wind turbine manufacturers have tried different controller schemes to make PWM circuits more versatile and reliable for controlling or limiting turbine speed in high wind. For a short course in PWM - CLICK HERE or CLICK HERE and have a read. You can even build a simple one yourself if you want to experiment CLICK HERE.

The OB1 Commander makes use of the basic PWM theory but now under much more versatile software control. The key is dynamic management of the pulses based on many input variables and this is best accomplished by using a dedicated microprocessor and some clever software algorithms that can be optimized for the blade and alternator performance as well as the changing wind conditions. Getting the most out of a particular airfoil and alternator combination is still a bit of a black art, since you can't really model all the local wind dynamics for every situation. In steady head-on wind it's a lot easier, but when speed and direction changes second by second you need an equally agile controller program that adapts itself to changing conditions and actually learns as it flies. . . the learning part, that's the future. For now OB1 will be smart enough to know where the power is in every wind it sees so it can adapt it's PWM controller output to capture the most available energy it can.

Here's some of the OB1 pre-production components I saw already going through QA and testing. The alternator is the large housing on the left of that long tube and the blades mount down wind . . on the right. Inside the center casing is the dual brush commutator and 6 bolt compression mount for the riser. It's a rugged machine that will fill a much needed product gap in the personal and remote power systems market.

So what's up with OB1 . . I saw more progress on the OB1 controller and the blade tooling and we are getting word they'll soon have the necessary funding to launch. . . unfortunately still no firm date as of 17 Jan 06, however, I expect to have a fully operational machine to begin testing in Canada within a few weeks March 2006. I've had a chance to play with the OB1 Commander on my LAKOTA last fall and was fascinated to see it "hunting" for the power sweet spot as the wind gusts change and flow. With a capability of up to 5kW this controller promises to be a really efficient turbine manager that can be retrofit to even competitor machines with a generic software load. The basic principles of Pulse Width Modulation (PWM) control have been around for decades with solar PV systems just line the LAKOTA heritage stems from Wind Baron Neo . . the world's first permanent magnet alternator small wind turbine. The breakthrough was the use of high powered Neodymium magnets. . . hence the name Neo.

With the development of the OB1, back in 2000, Aeromag produced the first microprocessor controlled PWM turbine. . . and now the OB1 Commander firmware has allowed that to be extended to the dynamic world of micro-gust management. The original patent for PWM controllers dates back to the early 80s. Since then many solar and some wind turbine manufacturers have tried different controller schemes to make PWM circuits more versatile and reliable for controlling or limiting turbine speed in high wind. For a short course in PWM - CLICK HERE or CLICK HERE and have a read. You can even build a simple one yourself if you want to experiment CLICK HERE.

The OB1 Commander makes use of the basic PWM theory but now under much more versatile software control. The key is dynamic management of the pulses based on many input variables and this is best accomplished by using a dedicated microprocessor and some clever software algorithms that can be optimized for the blade and alternator performance as well as the changing wind conditions. Getting the most out of a particular airfoil and alternator combination is still a bit of a black art, since you can't really model all the local wind dynamics for every situation. In steady head-on wind it's a lot easier, but when speed and direction changes second by second you need an equally agile controller program that adapts itself to changing conditions and actually learns as it flies. . . the learning part, that's the future. For now OB1 will be smart enough to know where the power is in every wind it sees so it can adapt it's PWM controller output to capture the most available energy it can.

Here's some of the OB1 pre-production components I saw already going through QA and testing. The alternator is the large housing on the left of that long tube and the blades mount down wind . . on the right. Inside the center casing is the dual brush commutator and 6 bolt compression mount for the riser. It's a rugged machine that will fill a much needed product gap in the personal and remote power systems market.

Upgrades to Commander

The LAKOTA Commander introduced last summer has been an excellent fool-proof method for connecting a turbine. . . althogh I've learned from an engineer friend of mine that "Nothing is FOOL-PROOF, given a sufficiently cunning fool". Connect three phase wires to any of the three phase terminals and as long as you can get RED and BLACK right on the battery connections you're done. While the first iteration of Commander was good this new one is even better. With feedback from Canadian installers last summer, they've made more room for the phase wires and battery connections and increased the size of the terminal blocks to handle up to AWG#3 wire if needed for 12v models. Also the terminal screws are standard flat head screws not the special 2.5mm hex wrench which made some installers with big fingers curse I'm sure. Getting that little Allen wrench in there with the limited wire space with #6 wire was always a bit of a test of will. On the new Commander there is finally an integrated blocking diode to protect its Load Diversion Regulator (LDR) from other system generators like solar PV or diesel. Until now the installer had to specify and add that component during installation, depending on the system configuration. Now it's built into every system. They've also added a new temperature control switch for the AUX fan on the Commander that will provide additional cooling when the heat sink back plane reached about 55 Dec C.

Here's a shot I took of one I got a chance to test, just finished at the factory last week. Lots more room to get those heavy phase wires in and the blocking diode is in that special heat sink you see next to the battery breaker.

The LAKOTA Commander introduced last summer has been an excellent fool-proof method for connecting a turbine. . . althogh I've learned from an engineer friend of mine that "Nothing is FOOL-PROOF, given a sufficiently cunning fool". Connect three phase wires to any of the three phase terminals and as long as you can get RED and BLACK right on the battery connections you're done. While the first iteration of Commander was good this new one is even better. With feedback from Canadian installers last summer, they've made more room for the phase wires and battery connections and increased the size of the terminal blocks to handle up to AWG#3 wire if needed for 12v models. Also the terminal screws are standard flat head screws not the special 2.5mm hex wrench which made some installers with big fingers curse I'm sure. Getting that little Allen wrench in there with the limited wire space with #6 wire was always a bit of a test of will. On the new Commander there is finally an integrated blocking diode to protect its Load Diversion Regulator (LDR) from other system generators like solar PV or diesel. Until now the installer had to specify and add that component during installation, depending on the system configuration. Now it's built into every system. They've also added a new temperature control switch for the AUX fan on the Commander that will provide additional cooling when the heat sink back plane reached about 55 Dec C.

Here's a shot I took of one I got a chance to test, just finished at the factory last week. Lots more room to get those heavy phase wires in and the blocking diode is in that special heat sink you see next to the battery breaker.

Pricing and the Use of Electricity EAST meets WEST

In the two tier electricity pricing system here in Ontario, they have increased the threshold for cheap power from 750kWhrs/month to 1000kWhrs . . but just for the winter months. . so come May they are dropping it to 600kWhrs. Here's how they describe it."For residential, seasonal and most farm customers, that means the threshold for lower-priced electricity increases from 750 kWh to 1,000 kWh on November 1. Each kWh of electricity you use above 1,000 is charged at the higher price of 5.8 cents per kWh. So using electricity wisely and keeping your monthly usage below 1,000 kWh will help you manage your bills. On May 1, 2006, the threshold for residential, seasonal and most farm customers will change again, decreasing from 1,000 kWh to 600 kWh for the summer season." In addition, starting in April (90 days from now) all electricity providers have been authorized to increase the basic price of energy sold to consumers every 6 months. . . so from now on, and twice a year, you can expect they will announce the new pricing . . . But . . as in the past the only announce the increase as a percentage increase in the "base energy price". Don't forget though, that what you pay includes all the additional charges that are all calculated on the base energy price, so the real % and $ increase in your bill will always be higher than the rate increase that is announced. Did you notice that dropping the threshold from 750 to 600 kWhrs it also increases your bill even if the basic energy price stays the same? . . . Perhaps they'll explain that in the next notice or maybe they'll have a "truth in advertising moment" and actually tell you how fast your whole bill will increase every six months . . . NOT!

So where does that actually leave the average consumer. . . Truly, most of Canada and particularly the subsidized northern communities enjoy very low direct evergy costs. Trouble is, the buried costs, like the extra taxes, infrastructure improvement costs and debt load is never counted as a cost for energy consumers. In reality, we continue to get closer to real world energy consumer costs, but the west has a long way to go in reducing overall personal and commercial energy consumption. At the rate of price increase we see today, I don't expect we'll approach the electricity cost experienced in Europe or the far east any time soon.

This past week in China, I've seen and experienced what expensive energy does to your thinking. China is a huge energy consumer because of it's size, but in parallel the real cost of power has forced them to think about the power they use and always make the best use of what they have. They don't waste it. They are always finding ways to use less . . . turn the lights off as soon as they are not needed . . keep the heat turned down in places where it's not needed . . . they wear more sweaters and coats indoors and they use a lot of localized heat at their desks, thereby avoiding heating large spaces when no one is there. You see hall lights that turn on as you approach and turn off after you leave . . no timer just a proximity sensor . . .You often see half the lights disconnected in a room when the whole room is not in regular full use. My hotel room has a smart card slot by the door. When you walk in you slip the smart card, room key into the slot and all the lights come on in the same configuration they were when you left. When you leave, you pull the card . . . and the lights all go out . . . but not until the second AFTER the door closes. . . VERY SMART!. Think how much that must save the hotel each year on a couple of hundred rooms. But the modern homes here also use that kind of technology, and if they can't afford the automation they simply do it manually, as a matter of course, without the fancy electronics. The sooner we get to that level of awareness the better.

Meanwhile, expect your hydro bill to go up until it hurts. If you care to know what it really costs today in Ontario click HERE

In the two tier electricity pricing system here in Ontario, they have increased the threshold for cheap power from 750kWhrs/month to 1000kWhrs . . but just for the winter months. . so come May they are dropping it to 600kWhrs. Here's how they describe it."For residential, seasonal and most farm customers, that means the threshold for lower-priced electricity increases from 750 kWh to 1,000 kWh on November 1. Each kWh of electricity you use above 1,000 is charged at the higher price of 5.8 cents per kWh. So using electricity wisely and keeping your monthly usage below 1,000 kWh will help you manage your bills. On May 1, 2006, the threshold for residential, seasonal and most farm customers will change again, decreasing from 1,000 kWh to 600 kWh for the summer season." In addition, starting in April (90 days from now) all electricity providers have been authorized to increase the basic price of energy sold to consumers every 6 months. . . so from now on, and twice a year, you can expect they will announce the new pricing . . . But . . as in the past the only announce the increase as a percentage increase in the "base energy price". Don't forget though, that what you pay includes all the additional charges that are all calculated on the base energy price, so the real % and $ increase in your bill will always be higher than the rate increase that is announced. Did you notice that dropping the threshold from 750 to 600 kWhrs it also increases your bill even if the basic energy price stays the same? . . . Perhaps they'll explain that in the next notice or maybe they'll have a "truth in advertising moment" and actually tell you how fast your whole bill will increase every six months . . . NOT!

So where does that actually leave the average consumer. . . Truly, most of Canada and particularly the subsidized northern communities enjoy very low direct evergy costs. Trouble is, the buried costs, like the extra taxes, infrastructure improvement costs and debt load is never counted as a cost for energy consumers. In reality, we continue to get closer to real world energy consumer costs, but the west has a long way to go in reducing overall personal and commercial energy consumption. At the rate of price increase we see today, I don't expect we'll approach the electricity cost experienced in Europe or the far east any time soon.

This past week in China, I've seen and experienced what expensive energy does to your thinking. China is a huge energy consumer because of it's size, but in parallel the real cost of power has forced them to think about the power they use and always make the best use of what they have. They don't waste it. They are always finding ways to use less . . . turn the lights off as soon as they are not needed . . keep the heat turned down in places where it's not needed . . . they wear more sweaters and coats indoors and they use a lot of localized heat at their desks, thereby avoiding heating large spaces when no one is there. You see hall lights that turn on as you approach and turn off after you leave . . no timer just a proximity sensor . . .You often see half the lights disconnected in a room when the whole room is not in regular full use. My hotel room has a smart card slot by the door. When you walk in you slip the smart card, room key into the slot and all the lights come on in the same configuration they were when you left. When you leave, you pull the card . . . and the lights all go out . . . but not until the second AFTER the door closes. . . VERY SMART!. Think how much that must save the hotel each year on a couple of hundred rooms. But the modern homes here also use that kind of technology, and if they can't afford the automation they simply do it manually, as a matter of course, without the fancy electronics. The sooner we get to that level of awareness the better.

Meanwhile, expect your hydro bill to go up until it hurts. If you care to know what it really costs today in Ontario click HERE